Technique data

Voltage:100-240V

power:curved 60W corner 39W

Heating plate temperature:200 Centigrade ± 5%

Arc heating plate size:100mmX50mmX2

Corner heating plate size:100mmX2.5mmX2

Curved softening time (2.5mm thickness, temperature 20 Centigrade):about 9 seconds

Bending angle softening time (2.5mm thickness, temperature 20 Centigrade):about 3 seconds

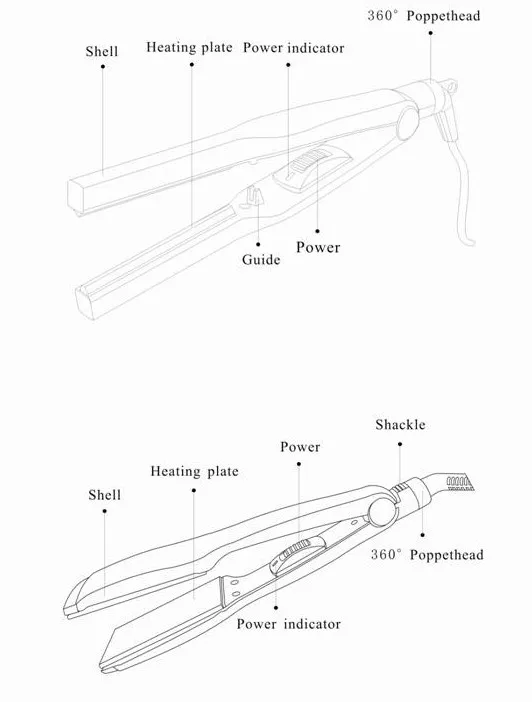

Benders for channel letters features:

Type A acrylic round bender/ corner bender is the better tool for acrylic luminous characters regula heating. It is the upgrading products of former heating tools, which adopting PTC heating set for energy saving, safety, fast heating, longer life-span, auto constant temperature, no complex temperature adjusting setting, easy operating.

Aluminum thermal plate is for even heating of regula, and auto-adjusting the angle between heating plate and regula which for 1.5-4mm thickness. The bender melt regula in short time, and no smoke during heating, no-stick plate by special oxidized treatment of heating plate surface. Taking high quality heat-resistant plastic for practial shell design, no more positioning required by buttom surface balance which easy for <100mm regula processing.

Operation for TWO Tools:

Round Bender:2.5mm thickness,about 9 seconds

Corner Bender:2.5mm thicknessm,about 3 seconds

Turn on round bender/ corner bender,then bend pieces after about 60 seconds heating. Let the round bender/ corner bender be perpendicular to (make end surface balance) acrylic panels. Nipping right position of acrylic piece, and making the bender fit acrylic piece well, then keep several seconds for heating. Move away round bender/ corner bender, fix the acrylic piece per letter curve, angle to get finished workpiece.

Company Information

Acrylic bender tool Sample photo